Projects

Testing and Trials

Testing and Trials

We can carry out strain guage installation and provide material laboratory standard test pieces for the major wind turbine manufacturers. We also have the ability of producing and testing materials and processes. We also can provide detailed reports on individual project as part of our quality system.

Global Homes

Global Homes

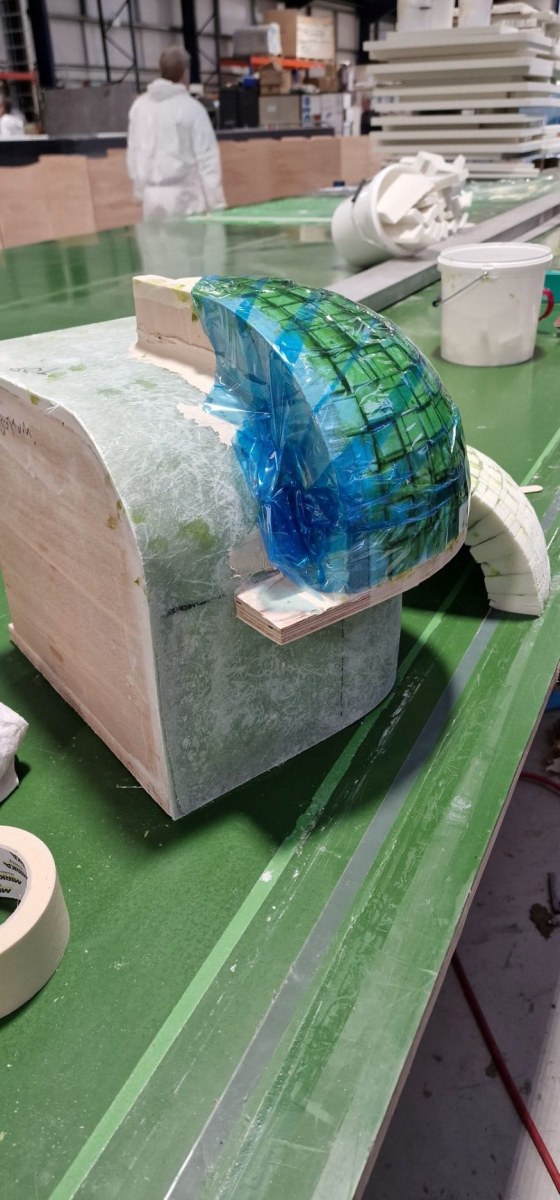

The was a step out of the ordinary for us. We were approached by the design team Medtec who wanted us to make mock up tooling for thois new Global home project. This design was to redesign how modern apartments were designed and manufactured. These radical new shapes would provide a new style of living space for modern aprtment dwellers. Walls would be moveable and there would be a central hub area for a library or games room. We developed these new and complex forms using new methods of forming MDF.

LM Blades

LM Blades

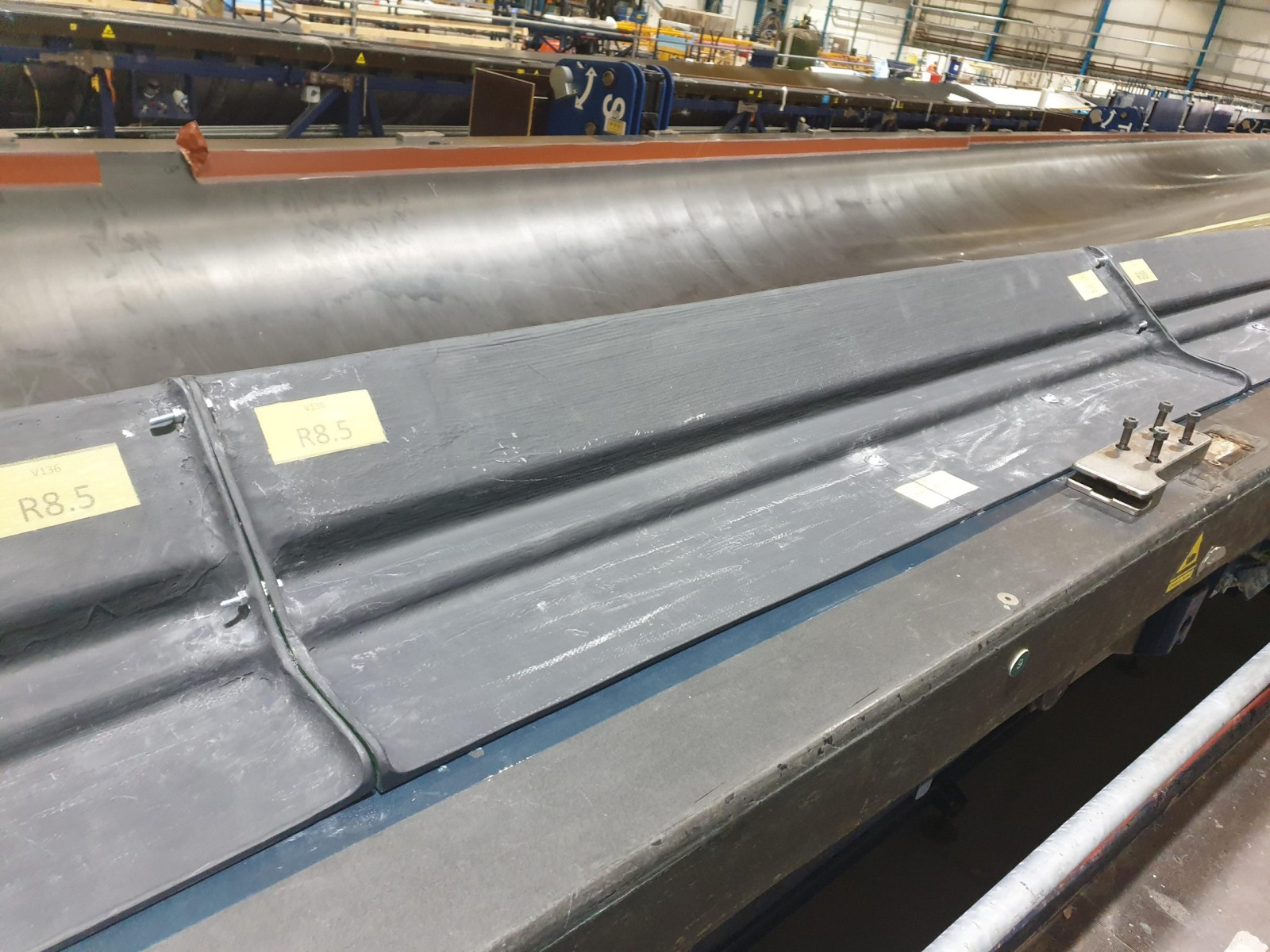

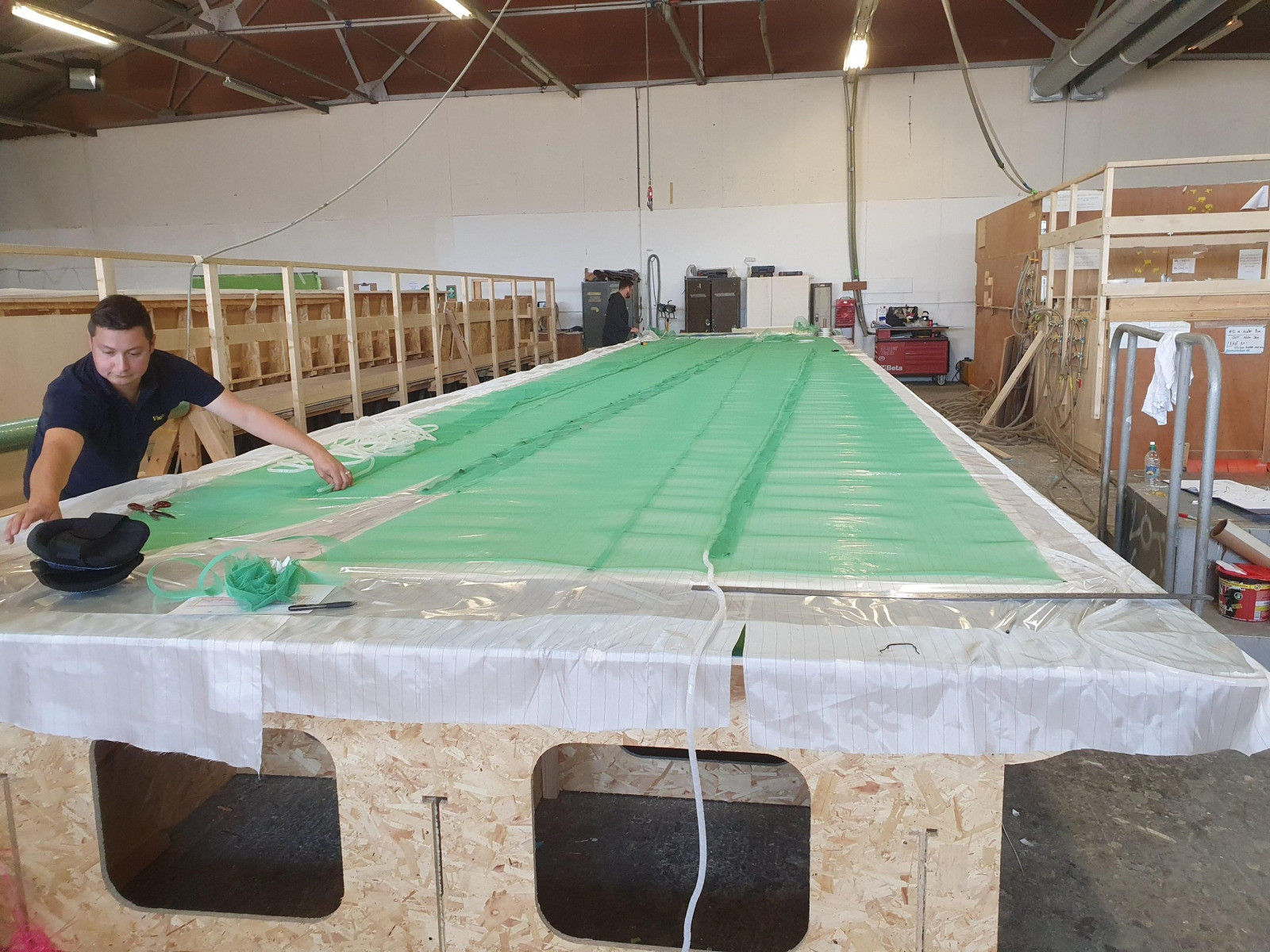

LM Blades which are now owned by GE, gave us a project to develop their thermoplastic infusion resin int a large scale part. This had not been successfully done before, but we achieved it. We made 13m long Leading edge and flat panels for them and continue to make checking and trial fixtures for them.

Wight Shipyard

Wight Shipyard

We have had a long relationship with boatbuilding dating back 30 years with Vision Yachts building highly successful one design race yachts. This relationship has continued through working with Wight Ship yard over the years. We have helped maintain composite parts on the Redjets and produced components for many of the companies designs.

Diamond Isle Boards

Diamond Isle Boards

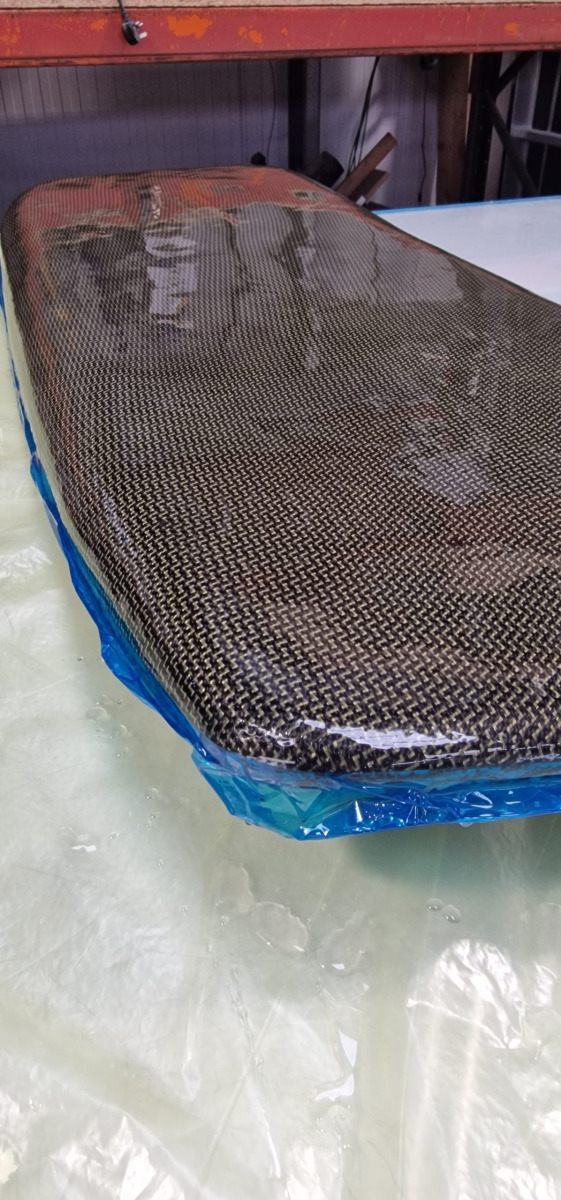

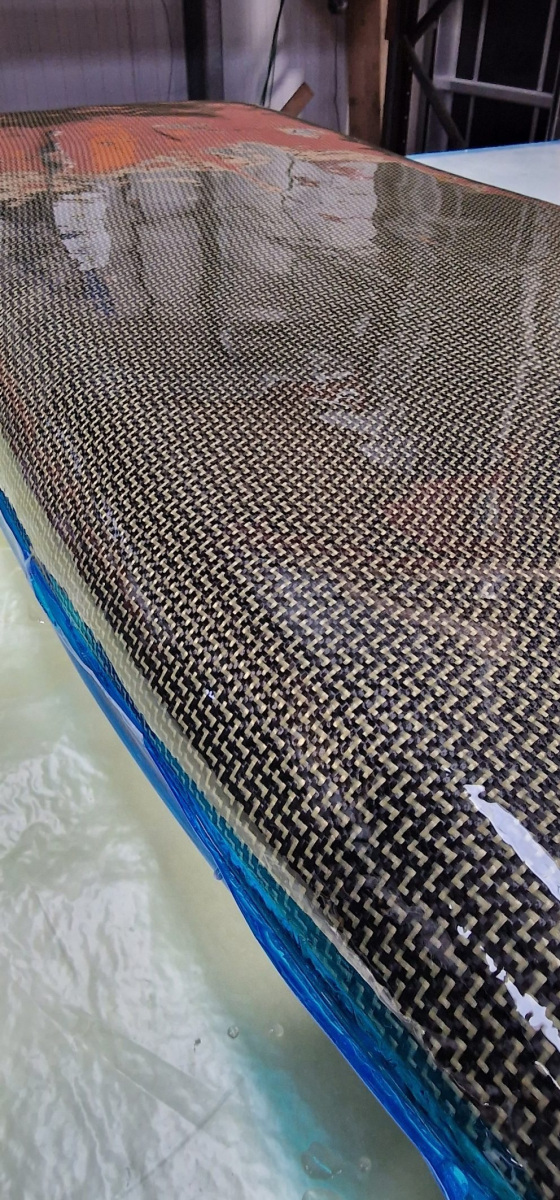

A new Vision project!! One of the directors is mad on watersports and has becone a Wingfoiler. This involves using a board with a hydrofoil attached to it, powered by a hand held inflateable wing. From this the brand 'Diamiond Isle Boards ' was born. Making cutting edge wingfoiling board for the public to enjoy. These are manufactured by shaping th efoam on our CNC machine and then laminating with carbon fibre. The first board has very recently been made and tested by Rob and passed it first flight trail. Development will refone to the perfect balanced board for many conditions. 2nd prototype under construction. Full Carbon lay up with new shape